Finishing Plastics to Your Exact Requirements

In today's competitive market, products need more than just functionality; they require a flawless finish to stand out. With over six decades of experience since our establishment in 1960, we possess the expertise and insight to deliver precisely finished parts every time.

The distinction between a superior part and an ordinary one often lies in the meticulous processes of cleaning, finishing, assembly, and secure packaging. We take immense pride in our commitment to manufacturing only top-tier parts that adhere to stringent specifications. Our rigorous deburring process includes comprehensive inspections, ensuring that each part is delivered to your exact specifications.

At the core of our success lies the philosophy of machining without creating burrs, thus eliminating the need for extensive deburring. Furthermore, we prioritize careful packaging to guarantee the safe transit of your products. From inception to delivery, our mission is to provide you with high-quality, impeccably finished products, promptly and without any shipping damage.

Laminated Plastics Finishing Options

What are finishing options? What can we offer that’s not already listed out?

Silk Screen, Engraving and Marking Plastic

We can deliver parts finished to your particular specification whether marked, pad printed, engraved, silk screened, etched, or coated.

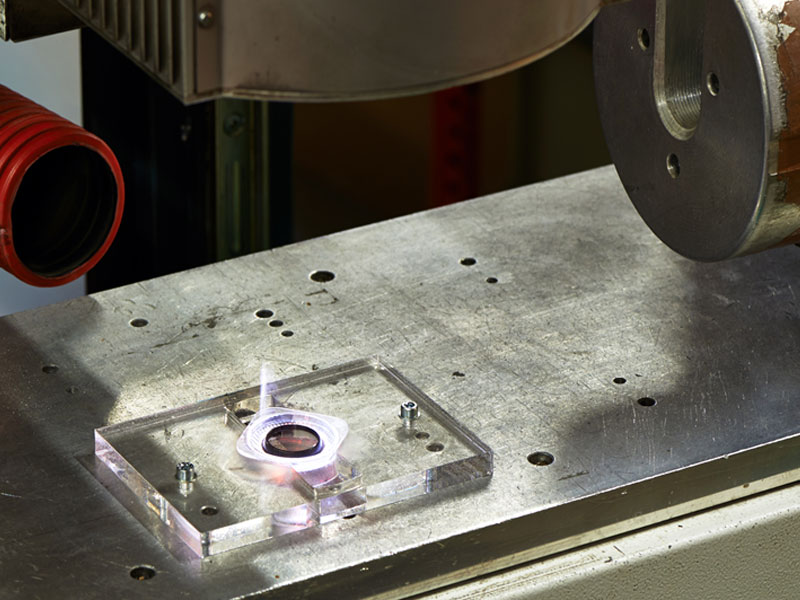

Assembly, Bonding and Welding Plastic

We have the capability to deliver assemblies consisting of various plastic or metal parts, which can be mounted conventionally, bonded, or welded. Our expertise in these techniques helps you reduce cost, promote quality, and improve safety.

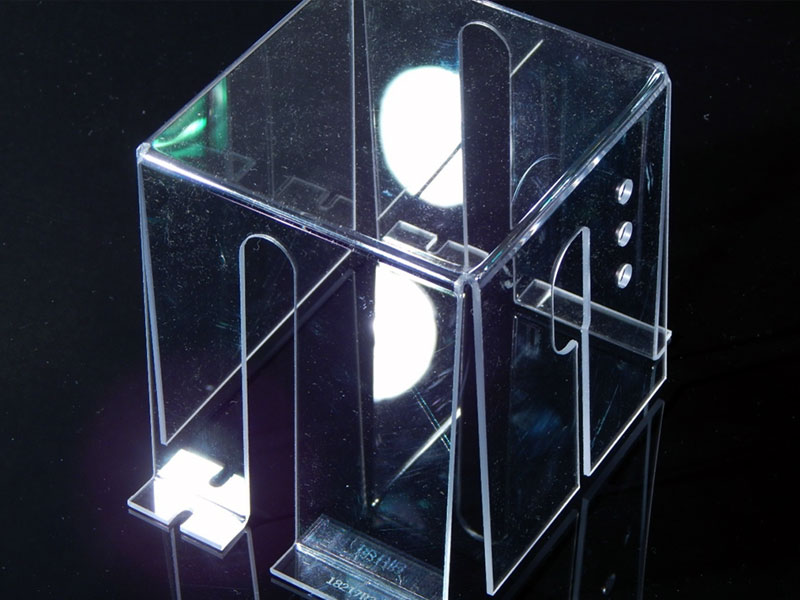

Buffing Plastic

Acrylic and other engineering plastics can be polished to esthetically improve the surface finish and enhance appearance.

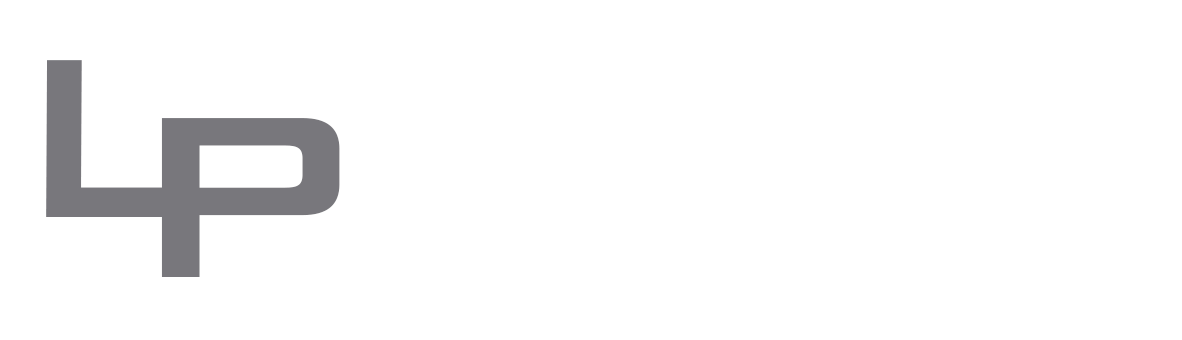

Flame Polishing Plastic

Flame Polishing produces one of the clearest finishes attainable. This method is most effective on flat, external surfaces and works best on acrylics. Flame polishing is frequently used on acrylic after the fabrication process because of its high speed when compared to other methods.

This process requires the surface of the acrylic or plastic material to be heated, creating material flow. Material, in a liquid state, will flow, allowing for a smoother finish.

Finishing and Secondary Operations for Plastics

Finishing operations include, but are not limited to, CNC Milling and turning, Pad Printing, hot stamping, part painting, precision fitting, and plastic parts assembly.