We are the Best in the Business

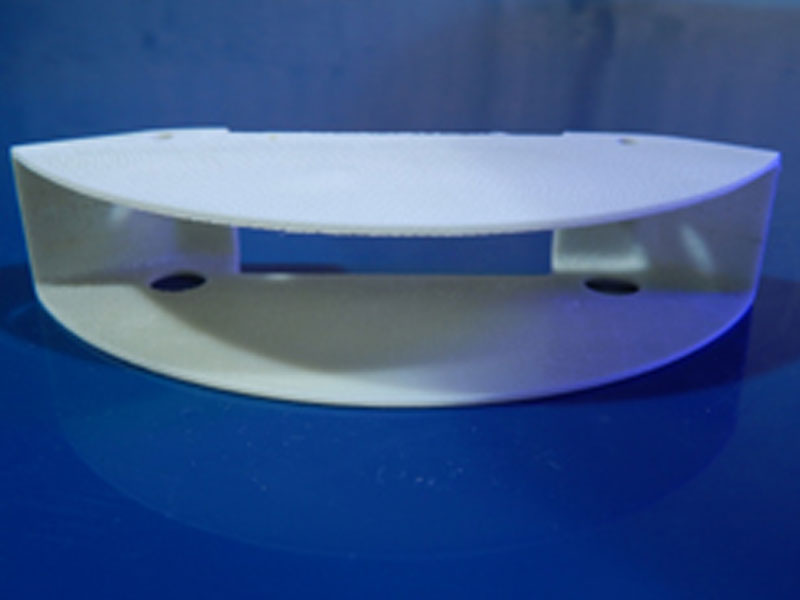

At our advanced manufacturing facility, our CNC operators are more than just machinists; they're seasoned professionals dedicated to precision. Our skilled specialists and programmers meticulously translate engineering plastics and laminate designs into your finished products. Leveraging cutting-edge technology ensures enhanced manufacturing versatility, while employing statistical process control, ensures greater efficiency and accuracy. We specialize in plastics machining and fabrication with capabilities that surpass expectations.

Specializing in Plastics Machining and Fabrication

We specialize in plastics machining and fabrication with capabilities that surpass expectations.

- Complex, intricate, and difficult machining.

- Precision and tight tolerance machining.

- Custom, high-volume OEM and short run machining.

- Prototype and "proof of concept" machining.

- Specializing in "tough" materials such as G-10, GPO, FR4 and phenoloic laminates.

Why is it Better to Machine Plastics and not Mold Plastics?

Our advanced forming process at Laminated Plastics offers cost-efficient solutions with lower mold costs, shorter lead times, and unparalleled design flexibility, including the ability to accommodate large-scale parts. Additionally, we provide secondary value-added options such as welding, bending, and bonding, allowing seamless customization of covers, panels, enclosures, housings, and any desired curvature to meet exact specifications.

- Cost-efficient solutions with lower mold costs and shorter lead times.

- Unparalleled design flexibility, including accommodation of large-scale parts.

- Secondary value-added options such as welding, bending, and bonding for seamless customization.

- Minimal tooling and no molds required.

- Tighter tolerances.

- Unlimited material options.

- Threads and undercuts with multiple angles are effortless.

Why Use Plastic and not Metal?

There are many advantages to using plastics over metal. These advantages include:

- Longer part life

- Reduced wear on matting parts

- Weight reduction

- Noise reduction

- Corrosion resistance

- Elimination of lubrication

Our High-Precision Machining Capabilities Include

Our State-of-the-art CNC equipment can create highly precise and intricate parts and components across a wide range of plastics. Here are some capabilities:

- CNC Router

- CNC 5 Axis Machining

- CNC milling

- CNC prototyping

- Micro machining

- Multi-spindle screw machining

Conventional Machining

Laminated Plastics also has expertise in conventional machining methods including:

- Turning

- Milling

- Grinding

- Drilling

- Tapping